Rotary Kiln

A rotary kiln is an inclined, rotating cylindrical reactor through which a charge moves continuously. The rotary kiln is a thermal processing furnace used for processing solid materials at extremely high temperatures in order to cause a chemical reaction or physical change. They are normally used to carry out processes such as (i) calcination, (ii) thermal desorption, (iii) organic combustion, (iv) sintering/induration, (v) heat setting, and (vi) many more processes.

Rotary kilns were originally developed for use in the cement industry. Due to their flexibility, they are now be found in use throughout a variety of industries, aiding in both processing commodities, as well as in highly specialized applications. They have also become the backbone of many new industrial processes.

Rotary kiln is used to heat solids to the point where a chemical reaction or physical change takes place. It works by holding the material to be processed at a specified temperature for a precise amount of time. Temperatures and retention times are determined through creating temperature profiles, based on thorough chemical and thermal analyses of the material.

Rotary kiln is comprised of a rotating cylinder (called the drum), sized specifically to meet the temperature and retention time requirements of the material to be processed. The kiln is set at a slight angle, in order to allow gravity to assist in moving material through the rotating cylinder.

Rotary kiln can be either of the direct-fired type, or the indirect-fired type. In a direct-fired kiln, a fuel is burnt in the drum, and the material is processed through direct contact with the flue gas. In an indirect-fired kiln, material is processed in an inert environment, and is heated through contact with the shell of the kiln, which is heated from the outside to maintain an inert environment.

The furnace walls (normally lined) make intermittent contact with the flue gas and the charge. Heat required for the various physical and chemical processes is delivered to the charge by lifting and overturning the charge as it moves through the interior of the rotary kiln

The first proposal for using a furnace defined in this way is perhaps that found in an English patent of 1865. The first rotary kiln was manufactured around 1885, but not until 1895 was the rotary type considered a success. The most widespread application of this principle today is in the production of cement clinker. Some of the other common applications for rotary kiln today include mineral roasting, sintering, calcining, iron ore reduction, lead-zinc volatilization from electric furnace dust, waste incineration, desorption of soil contaminants, upgrading of phosphate ores, recovery of waste lime, catalyst activation, activated carbon (C) production and re-activation, plastics processing, and ceramics processing.

Design elements

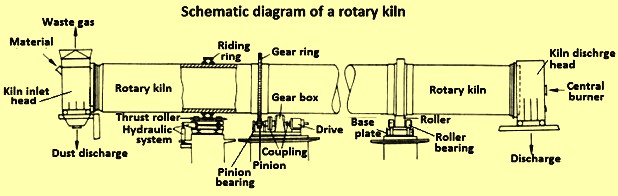

The essential design elements of a rotary kiln are shown in Fig 1 and Fig 2. The rotary kiln consists of a lined hollow cylinder, mounted in an inclined position on rolls and rotated slowly by a drive. The charge material moves from the feed end to the discharge end as a result of the rotary motion and gravity. The inclination of the kiln is between 1.5 % and 5 % and varies only in experimental kilns. Speed of the kiln ranges between 0.2 revolutions per minute (rpm) and 2 rpm. Normally variable-speed drives are used to control the residence time.

Fig 1 Schematic diagram of a rotary kiln

Kiln diameter is usually constant over the full length. Some rotary kilns have internals such as conveying or lifting flights, built in crossed-hanging link chains, or ring dams. In some processes, air-feed pipes or burner tubes for gas or oil are installed on the furnace shell. Air or other gases can also be introduced through ports in the lining.

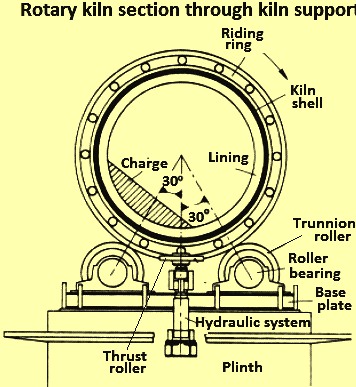

Fig 2 Rotary kiln section through kiln support

Rotary kiln structural components

Various structural components of the rotary kiln are described below.

Kiln shell – The steel shell of the kiln is conically tapered at the ends and can also have other tapered sections. It experiences torsion due to the drive, and flexural stress due to its own weight as well as the weight of the lining and the charge. Because of partial filling and point wise support, the ideally circular shell cross section is deformed into an oval shape. The shell is designed in accordance with the laws of thin-shell statics or by approximation methods. Direct-fired kilns are typically made out of C steel. Indirect-fired kilns, however, are to be more resistant to high temperatures, and are hence made out of a more heat-resistant alloy.

Drive assembly – The drive assembly is the component which causes the kiln to rotate. A variety of drive assembly arrangements can be used. These are chain and sprocket drive, gear drive, friction drive, and direct drive assembly. Unlike most other rotary kiln components, there is not a need for further customization in terms of the mechanical components of the drum. The need for one drive type over another is solely dependent on how much power is needed.

In case of a chain and sprocket arrangement, there is a large sprocket wrapping around the rotary drum with a chain on it which goes to the reducer and motor. The spinning motor turns a gear box, which spins a small sprocket which is attached by the chain to the large sprocket wrapping around the rotary drum. Chain and sprocket drive setups are generally used for small rotary kilns, running upto 55 kilo watts (kW) power. This type of arrangement is not suitable for larger rotary kilns needing more than 55 kW.

The gear drive is best for heavy-duty applications running above 55 kW. Similar to the chain and sprocket drive, instead of a sprocket wrapped around the girth of the drum, this drive has an actual gear around the drum. This gear meshes with a small gear drive, which rotates it.

Friction drive assemblies are used for small applications requiring low power. This is generally seen with drums having diameters around 2 m and below. With a friction drive, two of the four trunnion wheels are connected by one shaft and driven by a shaft mounted reducer and motor arrangement.

Direct drive assemblies are used in small to medium sized drums, with motors upto 55 kW power. In this design, a shaft is mounted to a solid, discharge end plate at the outlet of the kiln. The motor and reducer are either directly connected to this shaft with a coupling, or a shaft mount arrangement.

Riding rings – The riding rings provide a surface for the kiln load to be distributed. They help in supporting the furnace shell and are one-piece steel castings. Field-welded riding rings have also been used. Riding rings up to a diameter of 5 m are welded to the shell in some designs. Toothed riding rings are also common. Generally, however, especially in large-diameter kilns, riding rings are slipped loosely onto the thickened shell ring. The riding ring moves relative to the shell when in rotation. Correct sizing of the riding ring, play, and shell ring thickness are crucial for lining life in a kiln section. This represents a difficult design problem. Measurements of oval deformation with the ‘shell tester’ help the designer. Most of the kilns are supported at several points. Careful installation and maintenance of kilns are important. The alignment of long rotary kilns is critical for the load distribution on the riding rings and the shell.

Thrust rollers – Thrust rollers prevent the drum from drifting or moving horizontally by pushing against the riding rings. The trunnion wheels act as the cradle for the rotating drum shell. They ensure smooth and concentric rotation during operation. They also act as a wear piece, because they are easier and less costly to replace than the riding ring itself. The wheels are mounted to steel support bases with sealed roller bearings. Support rollers bear the weight of the drum. Two smooth trunnion rolls per riding ring, shrunk onto journals, generally turn in plain bearings with immersion or pressure-flow lubrication. Antifriction bearings are also sometimes used. One or more thrust rolls arranged parallel to the kiln axis, bear the downslope forces exerted by the kiln. These have hydraulic position adjustments so that the kiln can be moved in the longitudinal direction.

The kiln is rotated by a gear ring which is elastically attached to the shell and is driven by one or two pinions (depending on the drive torque). Frequency- controlled multiphase motors allow continuous control of rotational speed with very little loss of energy. In case of malfunction, mechanically or electrically actuated couplings can be used to engage an auxiliary drive (electric or internal combustion motor) to keep the kiln turning slowly and prevent damage due to overheating on one side.

Kiln discharge head – The kiln discharge head serves two purposes. One purpose is to provide a place for product to leave the kiln, so that it can move on to subsequent processing. The second purpose is to mount the kiln burner in a counter-current system. The product discharge area is where product leaves the kiln. Typically, the product then moves on to cooling or subsequent processing if needed.

Kiln inlet head – The Kiln inlet head has exhaust gas system which is typically much larger when working with a direct-fired kiln. Here, exhaust gases and any small particulates leave the system and typically go through exhaust gas treatment to remove contaminants before being discharged into the environment or sent to waste heat gas boiler for waste heat recovery. The exhaust gas system on a kiln often needs an afterburner and heat exchanger or quench tower to cool the gases before they enter the bag filter.

Kiln refractories – Refractory serves the purpose of insulating and protecting the shell of the drum from the high temperatures within, and also minimizing heat loss. Refractory lining is an important component of the rotary kiln. An important factor determining the service life of the refractory lining is the mechanical stability of the shell. The thickness, physical properties, and chemical composition of the refractories used for the lining are decided by the process to be carried out. For example, in the kiln used for iron ore reduction, low-iron alumina or magnesium – spinel bricks are used, while in a cement kiln usually magnesite brick lining in the clinker zone and acid-insulating brick made from silicate compounds in the preheating zone are used. Interlocking bricks (with tapered groove and tongue) are used in large diameter rotary kilns. Monolithic refractories are also used in some applications. Qualities of refractories and lining techniques improve significantly the service life of linings. Insulating bricks lining is very desirable for heat retention but have not proved useful in kilns in larger diameter kilns.

Burner – The burner of a rotary kiln supplies the energy required by the process. Instead of utilizing a combustion chamber, typically the burner on a kiln is mounted on the kiln discharge head. Burners can be designed to accommodate a variety of fuels such as gaseous, liquid, or solid fuels. Choosing the suitable burner for a rotary kiln is integral to ensuring efficient processing.

Raw material feed – The raw material feed, or feed chute, is where feedstock enters the drum. This is typically carried out using a feed screw or chute and is often made from a more heat-resistant alloy. This area is required to be designed in a robust manner so as to lessen the opportunity for build-up to occur.

Seal – The seal connects the stationary heads on the two ends to the rotating drum, and helps to prevent the escape of process gas from the system, as well as prevents air from leaking in. Holding the appropriate temperature within a rotary kiln is what allows the desired chemical reaction to occur. Sustaining this temperature, however, can be difficult if the right seal is not chosen. Various seal options exist.

Rotary kiln process

The rotary kiln carries out several functions simultaneously. It is a device for conveying, mixing, heat transfer, and reaction. These functions are needed to be in harmony. The charge in the kiln moves both radially and axially. Radial motion is determined by the degree of filling (percentage of cross-sectional area occupied by the charge) and the rotational speed. The angle of repose and the kiln inclination govern axial motion.

The interior of the charge tends to have a higher bulk density than the exterior, and grain size increases toward the outside. This tendency can be counteracted by the internals, which also improve heat transfer into the charge. Dust production can be limited by pelletizing the feed.

Heat transfer occurs principally from the combustion gas (generated by a burner usually installed at the discharge end of the kiln) to the charge. The driving force is normally the temperature difference. The gas can move co-current or counter-current to the longitudinal motion of the charge. Co-current gas flow is advantageous only when the charge temperature does not have to exceed a certain value. The counter-current arrangement is preferred. The different types of heat transfer in a rotary kiln are (i) heat transfer to material by gas radiation and convection, (ii) heat transfer to material by brick radiation, (iii) conductive heat transfer to material from brick, and (iv) heat transfer to brick by radiation, convection, and (v) heat loss by shell radiation and convection.

Rotary kiln sizing and design

Every material is different in terms of how it behaves in the kiln and at what temperatures different reactions are going to occur. When designing a process around a rotary kiln, as well as in the design of the kiln itself, the material is required to undergo thorough chemical and thermal analyses. Various material characteristics play a part in how the material is going to perform in the kiln, and subsequently, how the kiln is to be designed around the material to accomplish the process goal. The following provides an overview of some of the normal material characteristics which can influence the design of the kiln.

Particle size distribution and bulk density – The particle size distribution and bulk density of the material influences the sizing of some kiln components. For example, a material with a high bulk density is likely to require more power, and hence a more robust drive system is needed. In case, the material has been agglomerated into pellets (or has a larger particle size distribution) then it does not require as large of a kiln diameter as fines need. This is since when processing fines, a lower air velocity is to be used to minimize entrainment. When processing pellets, however, a higher air velocity can be utilized, and hence, the kiln does not need to have a larger diameter.

Abrasiveness and corrosiveness – While the abrasiveness or corrosiveness of the material does not have a direct effect on the sizing aspects of the kiln, it does influence the materials of construction. Working with abrasive or corrosive materials can require parts, or all, of the kiln to be lined or constructed with a corrosion/abrasion-resistant refractory.

Specific heat – The specific heat of a material is one of the important factors in the design of a rotary kiln. Specific heat is how resistant a material is to heating. By definition, it is how much heat energy it requires to raise 1 gram of material by 1 deg C. Some materials, such as water, have a very high specific heat, meaning it takes a significant amount of heat energy to raise the temperature. Other materials, such as metals, have a much lower specific heat, meaning it takes much less heat energy to cause a change in temperature.

Heat of reaction – In many kiln applications, heat is needed for a reaction to occur. For example, in the calcination of limestone (CaCO3) to lime (CaO), energy is needed to dissociate CaCO3 into CaO and CO2. In addition to energy, a high temperature is needed for most reactions to occur, the dissociation of limestone does not happen at a temperature below 900 deg C.

Thermal conductivity – Similar to specific heat, the thermal conductivity of a material also plays a part in the design of a rotary kiln. How a material transfers heat has a direct effect on how the material behaves in the rotary kiln. Does it transfer its heat easily, causing even heat distribution and low retention time, or does it hold onto its heat, causing cold pockets of material, longer retention time, and possibly there is a need for additional accessories like dams or bed disturbers.

Temperature profiles – A thermal gravimetric analysis, or TGA, can be performed on a material to determine changes in mass as a function of temperature. A TGA describes the temperature ranges at which mass loss occurs. This is critical in determining the required temperature profile in a kiln. As an example, free water shows primary removal at around 100 deg C, where tightly bound chemical water shows a mass loss upwards of 250 deg C.

A TGA also helps to show where a reaction begins, and ends, as often, the curve on a TGA starts at a specific temperature, but does not complete until a much higher temperature. Overall, a TGA helps determine the temperature profiles which are needed in a rotary kiln by showing at what temperature reactions are occurring. Additionally, while the intent of a process can be to convert a material in a specific way, a TGA reveals reactions which can occur between the start and end point, helping to indicate where unpredicted reactions can occur.

A differential scanning calorimeter (DSC) or differential thermal analysis (DTA) is also useful at this stage, as it shows the amount of heat required to perform the reactions and to heat the material to the final temperature.

Chemical composition – Knowing the chemical composition of a material is a valuable asset in rotary kiln design for many reasons. One important reason is that many materials burn inside the rotary kiln at high temperatures, creating more heat than is put into the rotary kiln. In cases such as these, the rotary kiln requires to be designed to withstand those excess amounts of heat. In other cases, materials can need a particular chemical atmosphere for a reaction to occur, for example, an atmosphere devoid of O2, or rich in CO2. Still another reason to understand the chemical makeup of a material, and how those chemicals react together at certain temperatures, is to predict what exhaust gases are generated and subsequently, what type of exhaust gas treatment is necessary.

Kiln sizing – After the material has been thermally and chemically analyzed, sizing of the kiln can begin. Sizing is a complex process and it is not easily explained in brief. The process of sizing a rotary kiln is one which combines engineering principles with the thermal and chemical analyses, along with experience, to design a kiln which meets its intended processing goal.

The size of a rotary kiln is not only a function of capacity, but also of the amount of heat which can be generated inside the rotary kiln from the volatizing and/or combustion of the material. The diameter and length of the rotary kiln are calculated based on the maximum feed rate, the required retention time, and what the bed profile (how full of material is in the rotary kiln) is required to look like.

In the design process, after the designer has engineered a rough design of the rotary kiln, he uses several computer programs to help predict and model how the material is going to behave in the rotary kiln which has been designed. The designer reviews the combined analyses, and if the design does not meet the appropriate criteria, the same is adjusted accordingly.

Once the preliminary rotary kiln size has been decided, the designer can start to think about the details of the rotary kiln internals, such as if there is going to be a need for a dam, or what type of refractory are needed to best suit the process.

Rotary kiln process application

Rotary kilns simply serve as a vessel to cause a chemical reaction or phase change. They are used for several types of processes. Some of the processes for which rotary kilns are used are described below.

Calcination – The calcination process requires heating a material to a high temperature with the intent of chemical dissociation (chemical separation). Calcination is generally used in the creation of inorganic materials. They are used for the calcination of limestone, dolomite, and magnesite.

Though coarsely crushed limestone can be converted to quick lime by heating in the shaft furnace, the rotary kiln is preferred for particle sizes of 60 mm or less since it delivers a more uniform product at a higher rate. This quick lime is particularly suitable for steelmaking and has been used in flue gas de-sulphurization. The rotary kiln also competes with the shaft furnace in the production of sintered magnesite and dolomite. As in limestone calcination, the rotary kiln offers the advantage of handling charge material of finer size with a broad size range and can also handle throughputs at high calcination temperatures.

The calcination process can also be used in the removal of bound moisture, such as that which is chemically attached in borax.

Production of cement clinker – Cement is produced almost exclusively in rotary kilns. Developments in clinker production have always spurred rotary kiln technology as a whole. Energy accounts for as much as 50 % of the total production costs of cement clinker. Energy saving approaches has led to thermally sophisticated, large- capacity rotary kilns. The trend is also toward using coal as the energy source. Long rotary kilns with slurry feed have increasingly been replaced by ‘heat-exchanger’ kilns (in which the raw feed is heated in upstream suspension-type heat exchangers. Development work with improved dust collection systems has led to lower energy consumption.

Reduction roasting – Reduction roasting is the removal of oxygen (O2) from a component of an ore usually by using a reductant such as carbon mono-oxide (CO).

The rotary kiln is used as a reduction furnace. It can employ a wide range of C carriers not suitable as reductants for shaft furnaces from anthracite and coke breeze to charcoal fines, lignite, and brown coal. The charge (ore and reductant) usually moves through the rotary kiln counter-current to the hot gases. Coupled reactions mainly ore reduction by CO gas and reaction of C with CO2 (carbon di-oxide) with regeneration of CO, occur in the charge. The reactivity of C is critical for the process as a whole. Some of the CO gas formed escapes from the charge so that oxidizing gases from the free kiln volume cannot permeate into it.

Reducing conditions depend on (i) the temperature, reactivity, and quantity of the reductant, (ii) the residence time, and (iii) the charge holdup at the discharge end of the kiln. The rate of reduction can be controlled to meet a variety of objectives, from the formation of magnetite (Fe3O4) to the production of direct reduced iron (DRI).

In magnetizing roasting, the iron content of lean ore is transformed to Fe3O4. The product is then concentrated by grinding and magnetic separation. The temperature profile and reducing conditions can be controlled with gas- fired or oil-fired shell heaters located along the kiln. Fuel is supplied to the rotating kiln through special seals. The reducing action can also be aided by the addition of small amounts of coal.

The most frequently used process is for the production of DRI. Lump ore, pellets, titano- magnetite-containing sea sand concentrates, zinc- and lead-containing residues from iron and steel production, and pellets from leach residues are reduced in rotary kilns.

Rotary kilns are also used for the exothermic roasting of sulphidic ores and for the endothermic removal of water of hydration and CO2 from fine-grained materials such as ores, phosphates, alumina, ilmenite, and titanium dioxide. These days, these processes are performed almost exclusively in fluidized-bed reactors, which offer better heat- and mass-transport conditions. However, rotary kilns have advantages where softening, sticking, or even partial melting of the material cannot be avoided.

Thermal desorption – Thermal desorption uses heat to drive off a volatile component, such as a pesticide, which has mixed with an inorganic mineral like sand. It is important to note that this is not incineration, which can produce harmful pollutants and can need a more extreme exhaust treatment system. Instead, it is a separation process which uses the different reaction temperatures of absorbent minerals and chemicals. The organic chemical (e.g. pesticide) is vapourized at the increased temperature, causing a separation without combustion. An indirect rotary kiln is best for this application, since the volatile chemicals can be combustible. The indirect kiln can supply the heat for desorption, without the material coming into direct contact with the flame.

Organic combustion – Organic combustion is the thermal treatment of organic waste with the intent of reducing mass and volume. This is generally seen in waste treatment plants to reduce the volume of waste for depositing in landfills. Direct-fired rotary kilns are the most common for this application, since air is needed to burn the organics.

Sintering/induration – Sintering is the process of heating the raw materials to a point just before melting. The objective of this process is to use the high internal temperature of the rotary kiln to increase the strength of the material. The most common use of this process is in the creation of manufactured proppants, (A solid material, typically sand, treated sand, or man-made ceramic materials, designed to keep an induced hydraulic fracture open, during or following a fracturing treatment), where the sand or ceramic material needs to have high strength.

Heat setting – This is a process of bonding a heat resistant core mineral with another, less heat resistant coating material. Much like other coating processes, there is a core material and a coating material (usually mixed with a binding agent). The difference between this process and a non-heated coating process is that a rotary kiln heats the coating material to just below its liquefaction point. At this heated state, the material can coat the heat resistant core evenly and, since this is a chemical phase change, more securely than a traditional coating process. A common application of this process is in the manufacturing of roofing granules, where a mineral such as granite is coated with a colored pigment, producing a durable and aesthetically pleasing granule.

Volatilization processes – Metals and metal compounds with a high vapour pressure can be recovered by volatilization from their raw materials in a rotary kiln. The volatilization can be enhanced by selective reduction. Examples include arsenic (As), antimony (Sb), lead (Pb), cadmium (Cd), mercury (Hg), silver (Ag), tin (Sn), and zinc (Zn) in elemental form or as compounds, for example, Zn as the metal and Pb as PbS or PbCl2. Waelz process has been used for decades in the volatilization of Zn and Pb.

Low Zn ores and other raw materials are fed together with solid reductants to the kiln, where the metal is volatilized under reducing conditions. The vapourized metal is oxidized in the free volume above the charge and recovered as dust (the so- called Waelz oxide) from the off gas. The Waelz process has also proved suitable for Zn and Pb containing residues from iron and steel production. Higher productivity with less energy consumption and less mechanical dust formation can be achieved by pelletizing the feed. The Waelz kiln oxide can be purified by washing with Na2CO3 solution.

Other applications – Other applications of the rotary kiln include (i) oxidation of ilmenite, (ii) calcination of iron ore pellets after preliminary heat treatment on a traveling grate, (iii) calcination of petroleum coke, (iv) reduction of heavy spar, (v) processing of gypsum to sulphuric acid and cement (gypsum – sulphuric acid process), (vi) production of TiO2 pigment, (vii) production of Hg, and (viii) volatilization of Zn , Pb, and copper (Cu) with CaCl2 etc.